When it comes to keeping a home comfortable and energy-efficient, insulation plays a starring role. Without proper insulation, heating and cooling systems work overtime, leading to high utility bills, uneven indoor temperatures, and even moisture problems. Two of the most common insulation options homeowners face today are spray foam insulation and fiberglass insulation.

So, the big question is: spray foam vs fiberglass—which insulation and why? The answer depends on factors like cost, performance, energy efficiency, and even the type of property. This article will walk you through the key differences, advantages, disadvantages, and real-world applications of both options so you can make an informed decision.

What Is Spray Foam Insulation?

Spray foam insulation is a high-performance insulation material created by mixing two chemicals—isocyanate and polyol resin—that react to form a foam. When applied, it expands up to 30–60 times its liquid volume, filling cracks, gaps, and cavities for a seamless barrier.

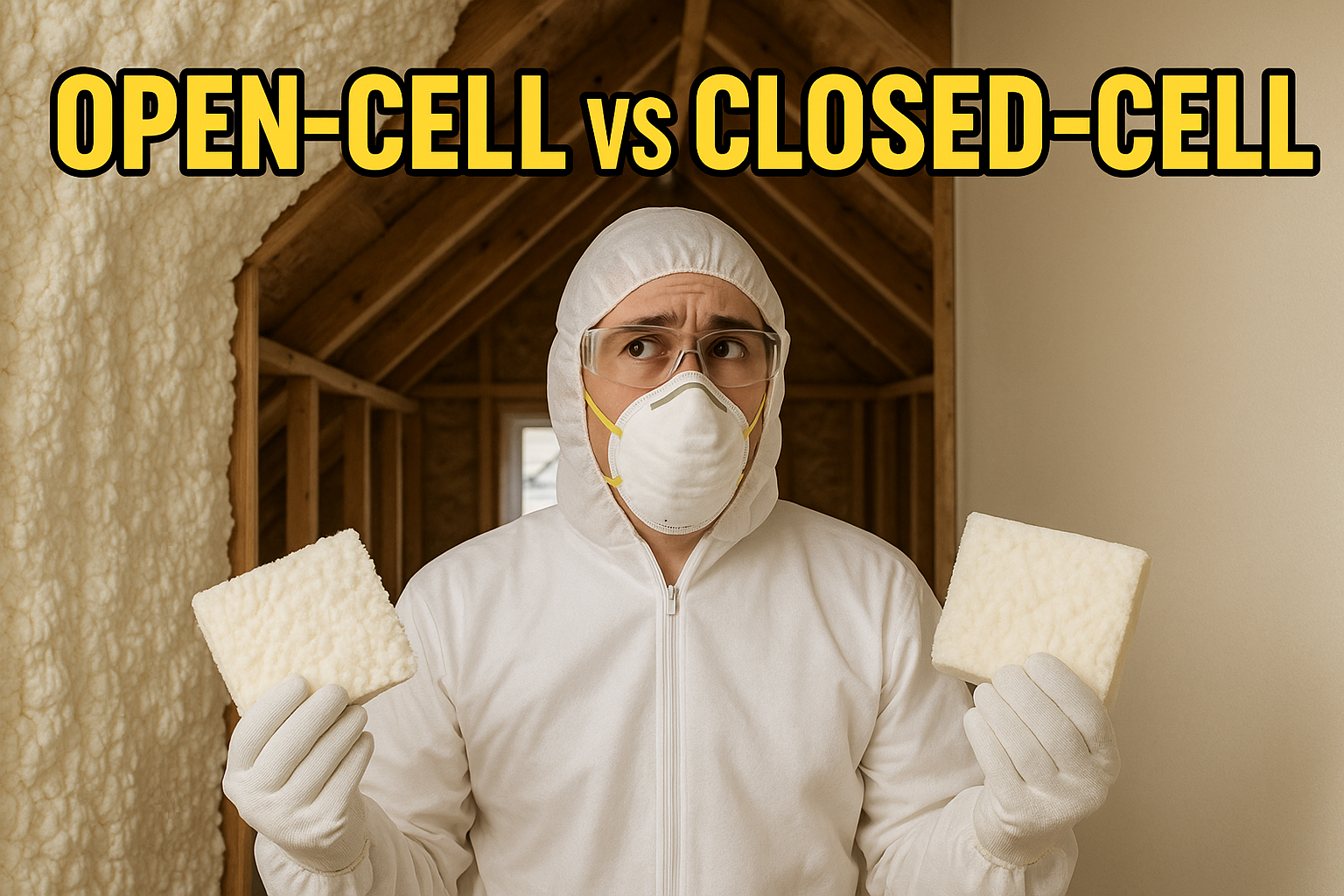

Types of Spray Foam: Open-Cell vs Closed-Cell

-

Open-Cell Spray Foam:

Softer, lighter, and more flexible. Provides good soundproofing but a lower R-value per inch. -

Closed-Cell Spray Foam:

Denser, more rigid, and provides superior moisture resistance and higher R-value. Often used in basements, crawl spaces, and exterior walls.

Key Properties and Applications

-

Excellent air barrier

-

High thermal resistance (R-value between 3.5 and 7 per inch)

-

Works well in hard-to-reach spaces like attics, rim joists, and crawl spaces

-

Strong resistance against mold and moisture

Find a Insulation Contractor Near You

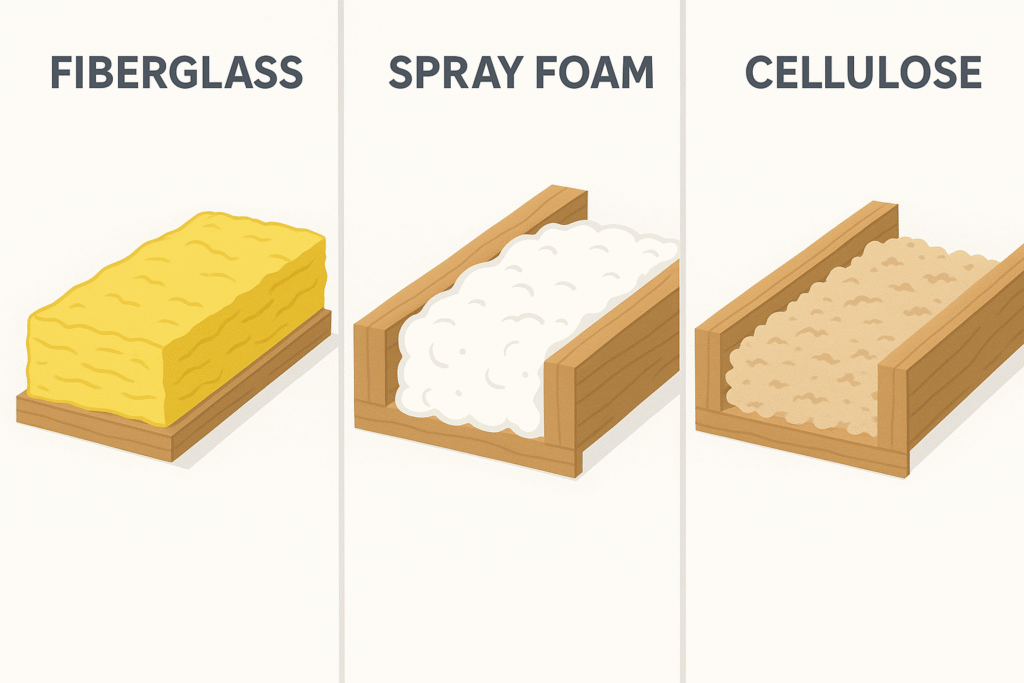

What Is Fiberglass Insulation?

Fiberglass insulation has been a trusted standard in homes for decades. It’s made from fine glass fibers spun into mats or rolls. Known for being cost-effective and widely available, fiberglass remains one of the most common insulation choices.

Types of Fiberglass Insulation

-

Batts and Rolls: Pre-cut sheets designed for standard wall cavities.

-

Blown-In Fiberglass: Loose-fill insulation blown into attics or wall cavities.

-

Rigid Fiberglass Boards: Higher-density boards used in HVAC systems and specialty applications.

Key Properties and Applications

-

R-value of 2.2 to 4.3 per inch

-

Affordable and easy to install (DIY-friendly)

-

Effective in attics, walls, and floors

-

Non-combustible and resistant to pests

Spray Foam vs Fiberglass: 11 Key Differences

Let’s dive into the head-to-head comparison that reveals the strengths and weaknesses of both insulation types.

1. R-Value and Thermal Performance

-

Spray Foam: Higher R-value (3.5–7 per inch), better at reducing heat transfer.

-

Fiberglass: Moderate R-value (2.2–4.3 per inch), may require thicker layers.

2. Air Sealing and Moisture Resistance

-

Spray Foam: Expands to seal cracks, excellent moisture barrier.

-

Fiberglass: Can leave gaps, vulnerable to air leaks and moisture absorption.

3. Installation Process

-

Spray Foam: Requires professional installation with special equipment.

-

Fiberglass: Can be DIY-installed, but improper handling reduces effectiveness.

4. Longevity and Durability

-

Spray Foam: Lasts 80+ years with little degradation.

-

Fiberglass: May sag, settle, or lose effectiveness over time.

5. Environmental Impact

-

Spray Foam: Made with chemicals, though newer eco-friendly options exist.

-

Fiberglass: Contains recycled glass but requires more material for equal performance.

6. Health and Safety Concerns

-

Spray Foam: Fumes during installation require ventilation.

-

Fiberglass: Can irritate skin and lungs if not handled with care.

7. Cost Comparison

-

Spray Foam: Higher upfront cost ($1.50–$3 per sq. ft. installed).

-

Fiberglass: Lower cost ($0.40–$1 per sq. ft. installed).

8. Energy Savings Potential

-

Spray Foam: Can reduce energy bills by 20–40%.

-

Fiberglass: Moderate savings but less airtight.

9. Noise Reduction

-

Spray Foam: Open-cell is excellent at soundproofing.

-

Fiberglass: Provides moderate noise reduction.

10. Versatility in Applications

-

Spray Foam: Ideal for irregular spaces and moisture-prone areas.

-

Fiberglass: Best suited for open wall cavities and attics.

11. Maintenance Requirements

-

Spray Foam: Virtually maintenance-free.

-

Fiberglass: Needs occasional replacement or adjustment.